Contact Supplier

Mr. Peter Han

Leave a message| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF,FCA,CPT,CIP |

| Min. Order: | 1 Set/Sets |

Basic Info

Model No.: CSK-15

Brand: Helper

Bonding Function: Structural Adhesive

Application: Construction

Material: Silicone

Classification: Room Curing

Additional Info

Packaging: Seaoworthy wooden case

Productivity: 16-18 pcs per minute

Transportation: Ocean

Place of Origin: China

Supply Ability: 5 sets per month

Certificate: ISO9001-2008

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,FCA,CPT,CIP

Product Description

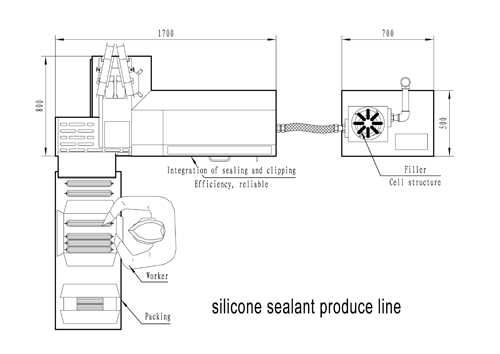

Introducing our top-of-the-line Silicone Sealant Produce Line, designed specifically for professionals seeking unparalleled quality and efficiency. This advanced system boasts cutting-edge technology, ensuring precise and consistent application every time. With its high-performance silicone formula, it guarantees exceptional adhesion and long-lasting durability, making it ideal for a wide range of applications. Our sealant produce line offers a seamless production process, minimizing downtime and maximizing productivity. Backed by rigorous quality control measures, this product line meets industry standards, delivering superior results that professionals can rely on. Upgrade your sealant production with our Silicone Sealant Produce Line and experience unmatched performance and reliability.

About Silicone Sealant Produce Line

Automatic Sealant filling and packing system is consist of drum filling machine, Hot Sealing Machine and Clipping Machine. It is specially designed for the sealant industrial with many new technical amendment made for the sealant filling. The clipping system is driven by servo-motor with compact structure and reliable transmission.

Hydraulic Adhesive Filling Machine

This machine has electronic sensor, can control discharge automatically. It can avoid machine damage and increase the accuracy of sub-package, error within 3%. This machine has high power plunger with constant adhesive load, the speed of sub-package is about 600 L per hour.

This machine has electronic sensor, can control discharge automatically. It can avoid machine damage and increase the accuracy of sub-package, error within 3%. This machine has high power plunger with constant adhesive load, the speed of sub-package is about 600 L per hour.

1. The maximum pressure: 160 tons.

2. Ordinary working pressure: 100 tons.

3. Voltage: 380 V Weight : 850 KG

4. Dimension: main machine: 2660*920*760 mm

5. Working table: 1000*800*620 mm

6. It is advised to use 68# anti-wear hydraulic oil 150 L.

RH Hot Sealing Machine

The machine is a necessary used between filling machine and clipping machine which plays an important role in high efficient continuous production line. Its function is forming tube with Polymer-aluminum composite packing film packaged in rolls. It adopts single-chip microcomputer automatic control, can connect with filling machine and clipping machine to form producing line, also can operate standalone. The tube forming package appearance is neat and tidy. Its characteristic is to improve the production efficiency and reduce working time and cost. (The main function of portioning cylinder is to improve the glue feeding speed and reduce the portioning error)

The machine is a necessary used between filling machine and clipping machine which plays an important role in high efficient continuous production line. Its function is forming tube with Polymer-aluminum composite packing film packaged in rolls. It adopts single-chip microcomputer automatic control, can connect with filling machine and clipping machine to form producing line, also can operate standalone. The tube forming package appearance is neat and tidy. Its characteristic is to improve the production efficiency and reduce working time and cost. (The main function of portioning cylinder is to improve the glue feeding speed and reduce the portioning error)

Main technology parameter:

1. Height of center : 900~10350 mm

2. Tube diameter:Ф 46.8 mm (can be adjust according to requirement).

3. Suitable material:aluminum composite membrance film

4. Dynamo method: pneumatic

5. Width of film: 160 mm (can be adjusted according to your require)

6. Temperature range: 0~200℃

Mechanical Greatwall Double Clipping Machine

By connecting with different types of heat-sealing machines produced by our company to form a complete production line with function of filling, sealing, cutting, this machine can improve your product quality and increase the yield greatly. With compact structure and reliable running PLC controlling, this machine completes the clipping function by a variety of CAM group. Main body and key parts are all made of stainless steel. Comprehensive mechanical properties and corrosion resistance ability can meet your production needs. The speed is adjustable as a result of the servo motor, PLC control.

Product Categories : Chemical Machinery

Hot Products